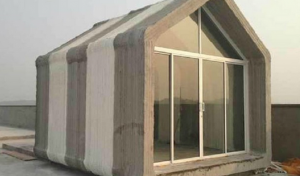

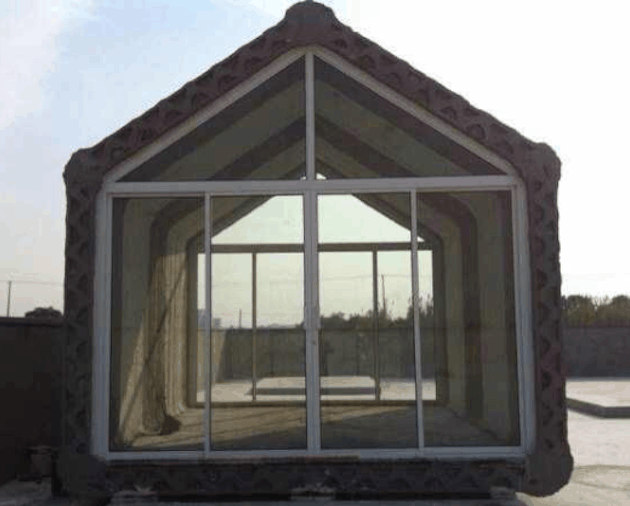

Chinese Company Assembles 10 3D-Printed Affordable Houses in a Day

OK so they are not pretty and wouldn’t feature on Grand Designs but never the less this is a remarkable achievement and a huge step forward in the development of 3D printed architecture. The possibilities this could bring are endless and considering the cost of each unit was a meager $4,800.00 it certainly comes to mind these could be used to provide emergency housing by areas affected by natural disasters and wars. This is a far cry from the stylish 3D printed Canal Houses in Amsterdam by DUS architects but it

does lead they way into 3D printed affordable housing.

The Shanghai building company, WinSun Decoration Design

Engineering Co. recently constructed a small community of partially 3D-printed houses in less than a day. The Chinese company printed the basic components separately before assembling them on site.

A 3D printer measuring 150 meters long, 10 meters wide, and 6 meters deep was used to 3D print each of the structural components from the giant concrete slabs to the inner cross bracing. As a cost cutter, WinSun fabricated the frame from layers of concrete partly made from recycled construction waste, industrial waste, and glass fibers.

The company also plans to open 100 recycling factories in the country to continue to transform waste into cost-effective “ink” for their 3D printers. Winsun estimates that this kind of 3D printing could cut costs for construction companies in half.

Trackbacks